| P

R O

D

U C T S |

AUTOMATIC

VENEER PLANER / Dynaparq Series |

| LSV-610

|

|

LSV-610

Exclusively Designed

Now you can get a veneer /

short wood planer with a lower investment cost.

|

|

| |

OUTSTANDING

FEATURES: |

| |

Competitive Edge for Composite Parquet Production

The Dynaparq series veneer planer produces fine surface effect without dusts on veneer surfaces. The veneers, after cut, can be glued directly for lamination. This increases production efficiency.

|

Greatly Lower Investment Cost

The price of Chen Sheng veneer planer is much lower then that of veneer or short wood machining equipment on the market.

|

Saving Production Costs

• Conventional veneer or short wood machining equipment requires considerable costs for cutting tools or other consumable parts.

•

The knives on Chen Sheng veneer planer can last one month for greatly saving cost.

|

High Speed Planing !

High Throughput !

Create More Profits !

Chen Sheng veneer planer provides higher production speed than other equipment.

|

Applicable Materials :

•

Wood

•

Plastic

•

Acrylic |

|

| |

|

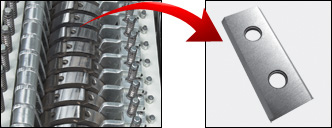

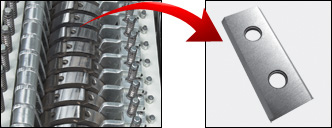

TWO SPIRAL CUTTERHEADS

- The planer is equipped with two oversized spiral cutterheads.

These spiral cutterheads provide high chip removable rate,

superior surface finish and extremely low noise while cutting.

- Manufactured from alloy steel, the spiral cutterheads are precision machined, tempered, dynamically balanced and precision ground.

|

|

TWO-EDGE KNIFE INSERTS

- The two-edge tungsten carbide knife inserts are fitted in the helical slots of the cutterhead.

-

Knife insert sizes are 30 x 12 x 1.5mm or 15 x 15 x 2.5mm.

|

|

SECTIONAL PRESSURE SHOES

The front and rear pressure units are consisted of sectional pressure shoes. Each pressure shoe is spring loaded, and pressure can be adjusted individually. This allows for feeding several pieces of short wood at a time.

|

|

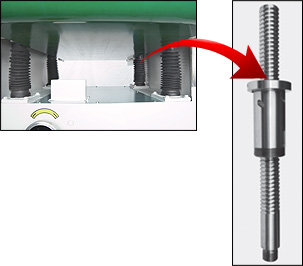

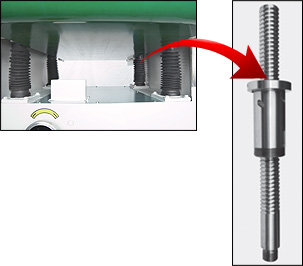

PRECISION BALL SCREWS SUPPORT

The table is supported by 4 big diameter precision ball screws, providing maximum wear resistance. The high precision ball screws greatly improve table positioning accuracy, which results in high accuracy of cutting thickness.

|

|

AUXILIARY FEED ROLLERS

- The infeed and outfeed end are individually equipped with auxiliary feed roller. These two additional feed rollers effectively increase feed motion smoothness.

- Both auxiliary feed rollers are covered by PU plastic to avoid scratching on wood surface.

- Both auxiliary feed rollers are spring loaded, ensuring extremely stable infeed and outfeed motions.

|

|

|

|

SPECIFICATIONS: |

| |

| MODEL |

LSV-610 |

|

Min. Working thickness (Veneer) |

1.5mm |

| Min. Working length (Short wood) |

3" |

|

Working width |

610mm |

| Working height |

150mm |

| Spiral cutterhead dia. |

Ø160mm |

|

Numbers of spiral cutterhead |

2 |

| Main motor standard

|

15HP |

|

Feed

motor |

1HP |

|

Table

hoist motor |

1/2 HP |

|

Feed speed (variable) |

4~20 m/min |

|

Net

weight |

1400 kgs |

|

Gross

weight |

1550 kgs |

|

Packing

dimensions |

75"(L) x 57"(W) x 68"(H) |

*

Specifications and design characteristics are subject to change without

prior notice.

|

| STANDARD

EQUIPMENT: |

1. Powered table elevation

2. Digital table positioning controls

3.

Two spiral cutterheads

4. 30 x 12 x 1.5mm knife inserts (Solid carbide)

5. Operation manual

6. Tool Box with Service tools |

| |

CHEN

SHENG MACHINERY INDUSTRIAL CO., LTD.

NO3, ALY 1, LN .198,SEC2,. SANFENG RD., FENGYUAN DIST., TAICHUNG CITY 420079, TAIWAN.

TEL:886-4-25221371 . 25228106 FAX:886-4-25241931 skype: chensheng07

|